Network Coupler (Constant Volume Chamber (TL))

Libraries:

Simscape /

Utilities /

Network Couplers

Description

The Network Coupler (Constant Volume Chamber (TL)) block uses a volume of fluid to break the connection between two networks. If your existing network has a suitable volume of fluid already modeled, then replace it with the fluid network coupler block. Otherwise, introduce a new volume of fluid to the system using the Network Coupler (Constant Volume Chamber (TL)) block. Try to make the volume of fluid representative of the dimensions of the part of the system where you are dividing the network, for example, use the volume of a connecting pipe. If you make the volume too small, it would require smaller step sizes, which would make real-time deployment more difficult.

Both of the port interfaces of the Network Coupler (Constant Volume Chamber (TL)) block are implemented as pressure and temperature sources. Therefore, you cannot connect this block directly to another volume of fluid or pressure source because this would cause an Index-2 topology (for more information, see Avoiding Numerical Simulation Issues).

Working with the Block on the Model Canvas

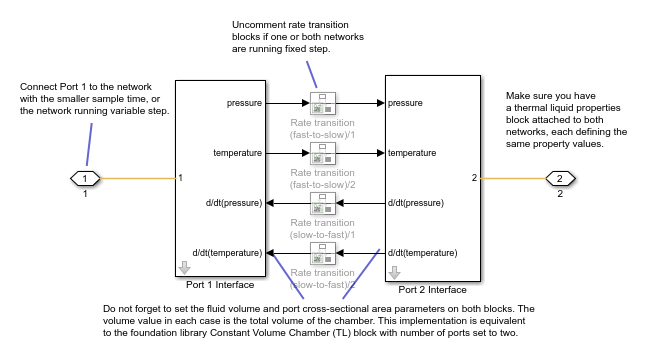

When you add the block to your model and double-click it, the Network Coupler (Constant Volume Chamber (TL)) subsystem opens.

The Port 1 Interface block contains the dynamics that break the algebraic loop. Double-click this block to set most of the Network Coupler (Constant Volume Chamber (TL)) subsystem parameters and view the derived values.

However, unlike most of the other coupler blocks, the Port 2 Interface block also has two parameters, Volume (m^3) and Port cross-sectional area (m^2), that you need to set separately.

The Network Coupler (Constant Volume Chamber (TL)) block is based on the

Foundation library Constant Volume Chamber (TL) block when it

has two fluid ports exposed. The coupler block implements a constant volume chamber using

two copies of the custom Simscape™ component partialChamberTL.ssc. Each of these partial

chambers models the full chamber, but calculates only the derivatives of pressure and

temperature due to flow into its fluid port. The coupler subsystem also contains two

Simulink® integrators, one for pressure and one for temperature, that sum and integrate

the derivatives from the two partial chambers. These Simulink integrators also break the respective algebraic constraint, one for pressure

and one for temperature, that would have existed if connecting two fluid networks directly.

Note

The Volume (m^3) parameter requested by the two subsystems is the total volume of the chamber in both cases, not half the volume.

The network coupler blocks break the transmission of fluid property data between the two networks. Therefore, you must attach a fluid properties block to both of the networks, setting fluid property values to be the same for each instance.

The rate transition blocks are, by default, commented through. Uncomment them if at least one of the coupled networks is running fixed step.

Using the Derived Values to Estimate Block Parameters

On the Analysis tab of the Port 1 Interface block dialog box, the Derived values section contains a list of recommended values that you can use when specifying block parameters. For example, use the Recommended max discrete sample time (s) derived value to verify that your Port 1 network discrete sample time (s) and Port 2 network discrete sample time (s) parameter values are within acceptable limits.

The derived values list is based on the chosen block configuration.

If both networks are running variable step, then the Analysis tab is empty, and there are no restrictions on the fluid volume value you specify.

If one or both networks are running fixed step, then the Analysis tab provides advice on the recommended maximum discrete sample time to use. To do this, you must provide some additional information about the connected networks:

Approximate connected network flow conductance, that is, the mass flow per unit pressure difference.

Approximate fluid density.

Approximate fluid bulk modulus.

These values only need to be approximate because they do not impact the model. They serve only to provide advice on the recommended maximum discrete sample time.

The Update button lets you recalculate the derived values after you change the parameters of the connected networks.