Magic Formula Tire Force and Torque

Apply steady-state tire force and torque by using Magic Formula tire equations

Since R2021b

Libraries:

Simscape /

Multibody /

Forces and Torques

Description

The Magic Formula Tire Force and Torque block implements the combined slip steady-state Magic Formula model and can optionally include turn slip effects [1]. You can use the block for tires that have square-like cross-sections, such as the tires of passenger cars, trucks, and off-road vehicles.

The block calculates only the tire force and torque. To model the geometry and inertia properties of the tire, you must use a solid block, such as the Cylindrical Solid block. The Magic Formula tire model assumes that tires are disks, as shown in the diagram.

The follower frame is at the center of the tire and rotates with the tire. The contact frame is at the contact point between the tire and the contact surface. The tire block has two methods to compute the location and orientation of the contact frame. For scenarios that require only single-point contact, use the closest point method. For driving conditions that require multiple-point contacts, use the weighted penetration method. For more information, see Contact Frame Method.

The image shows the contact and follower frames of the tire at zero configuration.

The yaw, camber, and spin angles correspond to a y-x-z sequence rotation about the follower frame of the tire.

To specify the properties of a tire model, generate a scalar structure array by using

the simscape.multibody.tirread function and enter the array in the

Tire Parameters parameter. The structure array must include all

the necessary tire parameters, while any extra parameters are ignored in the tire

modeling. For the list of required parameters, see Required Tire Parameters. The block uses the

ISO sign conventions.

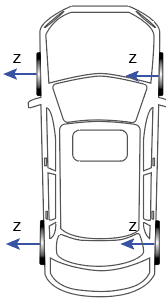

To specify the side of the vehicle to which a tire is mounted, use the Tire Side parameter. Specifying the wrong side can lead to unexpected simulation results. To correctly orient the tires on a vehicle, you must align the z-axes of the follower frames with the blue arrows shown in the diagram.

The signal output by the con port indicates whether the tire and the contact surface have a valid contact. If the tire and the surface are not in contact or the contact is not valid, all sensed outputs, such as the tire force, tire torque, and slip angle, become zero.

Ports

Geometry

Base geometry that represents the surface that the tire contacts. The contact surface can move or be fixed relative to the world frame. You must connect this port to an Infinite Plane or Grid Surface block.

Frame

Follower frame that represents the tire. The frame origin is located at the center of the tire.

Input

Physical signal port that accepts the scaling factor of the longitudinal friction coefficient of the tire.

Dependencies

To enable this port, under Scaling

Coefficients, set LMUX to

Provided by Input.

Physical signal port that accepts the scaling factor of the lateral friction coefficient of the tire.

Dependencies

To enable this port, under Scaling

Coefficients, set LMUY to

Provided by Input.

Output

Physical signal output port that provides a signal to determine

whether the tire and contact surface have a valid contact. When they are

in contact and the contact is valid, the signal equals

1, otherwise the signal equals

0.

If the follower frame is below the contact surface, the tire and the surface have an invalid contact and the block does not apply force and torque to the tire.

Dependencies

To enable this port, under Sensing, select Contact Signal.

Force/Torque

Physical signal output port that provides the magic formula tire force that is applied to the contact frame of the block. The output contains three parts:

Fx is the longitudinal force tangential to the contact surface at the contact point.

Fy is the lateral force which is orthogonal to the plane defined by Fx and Fz.

Fz is the normal force that is normal to the contact surface at the contact point.

The block resolves the force in the follower frame of the tire if you

set the Resolution Frame parameter to

Follower.

Dependencies

To enable this port, under Sensing > Force/Torque, select Tire Force.

Physical signal output port that provides the magic formula tire torque that is applied to the contact frame of the block. The output contains three parts:

Mx is the overturning moment.

My is the rolling resistance moment.

Mz is the aligning torque.

The block resolves the torque in the follower frame of the tire if you

set the Resolution Frame parameter to

Follower.

Dependencies

To enable this port, under Sensing > Force/Torque, select Tire Torque.

Physical signal output port that provides the distance from the contact point to the point of the resultant lateral force. The value has a unit of length.

You can use the pneumatic trail to compute the aligning torque, Mz.

Dependencies

To enable this port, under Sensing > Force/Torque, select Pneumatic Trail.

Slip

Physical signal output port that provides the ratio of the longitudinal slip velocity to the longitudinal speed of the tire.

Dependencies

To enable this port, under Sensing > Slip, select Longitudinal Slip.

Physical signal output port that provides the longitudinal slip saturated to always be within the limits defined by the KPUMIN and KPUMAX parameters.

Dependencies

To enable this port, under Sensing > Slip, select Saturated Longitudinal Slip.

Physical signal output port that provides the angle of the right triangle made by the lateral slip velocity, Vsy and the longitudinal speed, Vx. The value has a unit of angle.

Dependencies

To enable this port, under Sensing > Slip, select Slip Angle.

Physical signal output port that provides the slip angle saturated to always be within the limits defined by the ALPMIN and ALPMAX parameters. The value has a unit of angle.

Dependencies

To enable this port, under Sensing > Slip, select Saturated Slip Angle.

Physical signal output port that provides the ratio of the tire yaw velocity to the magnitude of the tire velocity in the xy-plane of the contact frame. The value has a unit of angle/length.

Turn slip is useful when modeling low speed cornering, such as parking maneuvers.

Dependencies

To enable this port, under Sensing > Slip, select Turn Slip.

Linear Velocity

Physical signal output port that provides the component of the relative velocity between the follower frame and the contact point on the base geometry along the x-direction of the contact frame. The value has a unit of length/time.

Dependencies

To enable this port, under Sensing > Linear Velocity, select Relative Longitudinal Velocity.

Physical signal output port that provides the component of the relative velocity between the follower frame and the contact point on the base geometry along the y-direction of the contact frame. The value has a unit of length/time.

Dependencies

To enable this port, under Sensing > Linear Velocity, select Relative Lateral Velocity.

Physical signal output port that provides the component of the relative velocity between the slip point on the tire and the coincident point on the base geometry along the x-direction of the contact frame. The value has a unit of length/time.

Dependencies

To enable this port, under Sensing > Linear Velocity, select Longitudinal Slip Velocity.

Physical signal output port that provides the component of the relative velocity between the slip point on the tire and the coincident point on the base geometry along the y-direction of the contact frame. The value has a unit of length/time.

Dependencies

To enable this port, under Sensing > Linear Velocity, select Lateral Slip Velocity.

Yaw

Physical signal output port that provides the first derivative of the yaw angle. The value has a unit of angle/time.

Dependencies

To enable this port, under Sensing > Yaw, select Velocity.

Camber

Physical signal output port that provides the camber angle of the tire. The value has a unit of angle.

Dependencies

To enable this port, under Sensing > Camber, select Angle.

Physical signal output port that provides the camber angle of the tire saturated to always be within the limits defined by the CAMMIN and CAMMAX parameters. The value has a unit of angle.

Dependencies

To enable this port, under Sensing > Camber, select Angle.

Physical signal output port that provides the first derivative of the camber angle. The value has a unit of angle/time.

Dependencies

To enable this port, under Sensing > Camber, select Velocity.

Spin

Physical signal output port that provides the first derivative of the spin angle. The value has a unit of angle/time.

Dependencies

To enable this port, under Sensing > Spin, select Velocity.

Tire Radius

Physical signal output port that provides the free radius of the tire. The radius increases as the tire rotates faster. The value has a unit of length.

Dependencies

To enable this port, under Sensing > Tire Radius, select Free Radius.

Physical signal output port that provides the distance from the center of the tire to the contact point between the tire and the contact surface. The value has a unit of length.

Dependencies

To enable this port, under Sensing > Tire Radius, select Loaded Radius.

Physical signal output port that provides the distance from the follower frame to the slip point. The value has a unit of length.

Dependencies

To enable this port, under Sensing > Tire Radius, select Effective Rolling Radius.

Physical signal output port that provides the difference between the free radius output from the romega port and the loaded radius output from the rl port. The value has a unit of length.

Dependencies

To enable this port, under Sensing > Tire Radius, select Radial Deflection.

Friction

Physical signal output port that provides the longitudinal friction coefficient of the tire computed by the magic formula equations.

Dependencies

To enable this port, under Sensing > Friction, select Longitudinal Friction Coefficient.

Physical signal output port that provides the lateral friction coefficient of the tire computed by the magic formula equations.

Dependencies

To enable this port, under Sensing > Friction, select Lateral Friction Coefficient.

Contact Frame

Physical signal port that outputs a 3-by-3 rotation matrix that maps the vectors in the contact frame to vectors in the reference frame of the base geometry. The output signal is resolved in the reference frame associated with the base geometry.

Dependencies

To enable this port, in the Sensing > Contact Frame section, select Base Rotation.

Physical signal port that outputs a 3-by-1 vector that contains the coordinates of the origin of the contact frame resolved in the reference frame of the base geometry.

Dependencies

To enable this port, in the Sensing > Contact Frame section, select Base Translation.

Physical signal port that outputs a 3-by-3 rotation matrix that maps vectors in the contact frame to vectors in the reference frame of the follower geometry. The output signal is resolved in the reference frame associated with the follower geometry.

Dependencies

To enable this port, in the Sensing > Contact Frame section, select Follower Rotation.

Physical signal port that outputs a 3-by-1 vector that contains the coordinates of the origin of the contact frame resolved in the reference frame of the follower geometry.

Dependencies

To enable this port, in the Sensing > Contact Frame section, select Follower Translation.

Parameters

Tire position during modeling, specified as either Left or

Right. Set the parameter to the side of the vehicle

to which the tire is mounted.

Tire parameters, specified as a scalar structure array. Use the simscape.multibody.tirread function to generate the

structure array from a TIR file. The structure array must include all the

necessary tire parameters, while any extra parameters are ignored in the

tire modeling. For the list of required parameters, see Required Tire Parameters.

Slip mode, specified as either Combined or

Combined + Turn.

To model combined slip, select Combined. To model combined

slip with turn slip effects, select Combined +

Turn. When selecting this option, the tire parameters

require the turn slip coefficients.

Turn Slip Coefficients

| PDXP1 | Peak FX reduction due to spin parameter |

| PDXP2 | Peak FX reduction due to spin with varying load parameter |

| PDXP3 | Peak FX reduction due to spin with kappa parameter |

| PKYP1 | Cornering stiffness reduction due to spin |

| PDYP1 | Peak FY reduction due to spin parameter |

| PDYP2 | Peak FY reduction due to spin with varying load parameter |

| PDYP3 | Peak FY reduction due to spin with alpha parameter |

| PDYP4 | Peak FY reduction due to square root of spin parameter |

| PHYP1 | FY-alpha curve lateral shift limitation |

| PHYP2 | FY-alpha curve maximum lateral shift parameter |

| PHYP3 | FY-alpha curve maximum lateral shift varying with load parameter |

| PHYP4 | FY-alpha curve maximum lateral shift parameter |

| PECP1 | Camber w.r.t. spin reduction factor parameter in camber stiffness |

| PECP2 | Camber w.r.t. spin reduction factor varying with load parameter in camber stiffness |

| QDTP1 | Pneumatic trail reduction factor due to turn slip parameter |

| QCRP1 | Turning moment at constant turning and zero forward speed parameter |

| QCRP2 | Turn slip moment (at alpha=90deg) parameter for increase with spin |

| QBRP1 | Residual (spin) torque reduction factor parameter due to side slip |

| QDRP1 | Turn slip moment peak magnitude parameter |

Method to use to compute the location and orientation of the contact frame, specified as:

Closest Point: This method determines the contact point by locating the point on the contact surface that is closest to the center of the tire and lies in the plane of the tire. The contact normal vector is at the contact point and perpendicular to the contact patch at the contact point.Weighted Penetration: This method simplifies the computation due to the irregularities of the contact surface and computes an equivalent plane at each simulation time step to approximate the actual contact area. The contact point is the nearest point on this equivalent plane to the center of the tire. The contact normal vector is at the contact point and perpendicular to the equivalent plane. For more information, see the description of Custom Tire Force and Torque.

For both settings, the contact frame is at the contact point and the z-axis of the frame is aligned with the contact normal.

Scaling Coefficients

Scaling factor for the longitudinal friction coefficient. Select From Tire

Parameters to use the constant scaling factor provided

by the TIR file, or select Provided by Input

to use input signals as scaling factors.

Scaling factor for the lateral friction coefficient. Select From Tire

Parameters to use the constant scaling factor provided

by the TIR file, or select Provided by Input

to use input signals as scaling factors.

Sensing

Force/Torque

Frame used to resolve the calculated tire force and torque, specified

as either Contact or

Follower.

More About

Scaling Coefficients

| LFZO | Scale factor of nominal (rated) load |

| LCX | Scale factor of Fx shape factor |

| LMUX | Scale factor of Fx peak friction coefficient |

| LEX | Scale factor of Fx curvature factor |

| LKX | Scale factor of slip stiffness |

| LHX | Scale factor of Fx horizontal shift |

| LVX | Scale factor of Fx vertical shift |

| LCY | Scale factor of Fy shape factor |

| LMUY | Scale factor of Fy peak friction coefficient |

| LEY | Scale factor of Fy curvature factor |

| LKY | Scale factor of cornering stiffness |

| LKYC | Scale factor of camber stiffness |

| LKZC | Scale factor of camber moment stiffness |

| LHY | Scale factor of Fy horizontal shift |

| LVY | Scale factor of Fy vertical shift |

| LTR | Scale factor of peak of pneumatic trail |

| LRES | Scale factor for offset of residual torque |

| LXAL | Scale factor of alpha influence on Fx |

| LYKA | Scale factor of alpha influence on Fx |

| LVYKA | Scale factor of kappa induced Fy |

| LS | Scale factor of Moment arm of Fx |

| LMX | Scale factor of overturning moment |

| LVMX | Scale factor of Mx vertical shift |

| LMY | Scale factor of rolling resistance torque |

| LMP | Scale factor of parking moment |

Mode

| TYRESIDE | Position of tire during measurements |

| LONGVL | Reference speed |

| VXLOW | Lower boundary velocity in slip calculation |

Dimension

| UNLOADED_RADIUS | Free tire radius |

| WIDTH | Nominal section width of the tire |

| ASPECT_RATIO | Nominal aspect ratio |

Operating Conditions

| INFLPRES | Tire inflation pressure |

| NOMPRES | Nominal pressure used in magic formula equations |

Vertical

| FNOMIN | Nominal wheel load |

| VERTICAL_STIFFNESS | Tire vertical stiffness |

| BREFF | Low load stiffness of effective rolling radius |

| DREFF | Peak value of effective rolling radius |

| FREFF | High load stiffness of effective rolling radius |

| Q_RE0 | Ratio of free tire radius with nominal tire radius |

| Q_V1 | Tire radius increase with speed |

| Q_V2 | Vertical stiffness increase with speed |

| Q_FCY | Lateral force influence on vertical stiffness |

| Q_FCY2 | Explicit load dependency for including the lateral force influence on vertical stiffness |

| Q_FZ2 | Quadratic term in load vs. deflection |

| Q_CAM1 | Linear load dependent camber angle influence on vertical stiffness |

| Q_CAM2 | Quadratic load dependent camber angle influence on vertical stiffness |

| Q_CAM3 | Linear load and camber angle dependent reduction on vertical stiffness |

| Q_FYS1 | Combined camber angle and side slip angle effect on vertical stiffness (constant) |

| Q_FYS2 | Combined camber angle and side slip angle linear effect on vertical stiffness |

| Q_FYS3 | Combined camber angle and side slip angle quadratic effect on vertical stiffness |

| PFZ1 | Pressure effect on vertical stiffness |

Inflation Pressure Range

| PRESMIN | Minimum allowed inflation pressure |

| PRESMAX | Maximum allowed inflation pressure |

Vertical Force Range

| FZMIN | Minimum allowed wheel load |

| FZMAX | Maximum allowed wheel load |

Long Slip Range

| KPUMIN | Minimum valid wheel slip |

| KPUMAX | Maximum valid wheel slip |

Slip Angle Range

| ALPMIN | Minimum valid slip angle |

| ALPMAX | Maximum valid slip angle |

Inclination Angle Range

| CAMMIN | Minimum valid camber angle |

| CAMMAX | Maximum valid camber angle |

Longitudinal Coefficients

| PCX1 | Shape factor Cfx for longitudinal force |

| PDX1 | Longitudinal friction Mux at Fznom |

| PDX2 | Variation of friction Mux with load |

| PDX3 | Variation of friction Mux with camber |

| PEX1 | Longitudinal curvature Efx at Fznom |

| PEX2 | Variation of curvature Efx with load |

| PEX3 | Variation of curvature Efx with load squared |

| PEX4 | Factor in curvature Efx while driving |

| PKX1 | Longitudinal slip stiffness Kfx/Fz at Fznom |

| PKX2 | Variation of slip stiffness Kfx/Fz with load |

| PKX3 | Exponent in slip stiffness Kfx/Fz with load |

| PHX1 | Horizontal shift Shx at Fznom |

| PHX2 | Variation of shift Shx with load |

| PVX1 | Vertical shift Svx/Fz at Fznom |

| PVX2 | Variation of shift Svx/Fz with load |

| RBX1 | Slope factor for combined slip Fx reduction |

| RBX2 | Variation of slope Fx reduction with kappa |

| RBX3 | Influence of camber on stiffness for Fx combined |

| RCX1 | Shape factor for combined slip Fx reduction |

| REX1 | Curvature factor of combined Fx |

| REX2 | Curvature factor of combined Fx with load |

| RHX1 | Shift factor for combined slip Fx reduction |

| PPX1 | Linear influence of inflation pressure on longitudinal slip stiffness |

| PPX2 | Quadratic influence of inflation pressure on longitudinal slip stiffness |

| PPX3 | Linear influence of inflation pressure on peak longitudinal friction |

| PPX4 | Quadratic influence of inflation pressure on peak longitudinal friction |

Overturning Coefficients

| QSX1 | Vertical shift of overturning moment |

| QSX2 | Camber induced overturning couple |

| QSX3 | Fy induced overturning couple |

| QSX4 | Mixed load lateral force and camber on Mx |

| QSX5 | Load effect on Mx with lateral force and camber |

| QSX6 | B-factor of load with Mx |

| QSX7 | Camber with load on Mx |

| QSX8 | Lateral force with load on Mx |

| QSX9 | B-factor of lateral force with load on Mx |

| QSX10 | Vertical force with camber on Mx |

| QSX11 | B-factor of vertical force with camber on Mx |

| QSX12 | Camber squared induced overturning moment |

| QSX13 | Lateral force induced overturning moment |

| QSX14 | Lateral force induced overturning moment with camber |

| PPMX1 | Influence of inflation pressure on overturning moment |

Lateral Coefficients

| PCY1 | Shape factor Cfy for lateral forces |

| PDY1 | Lateral friction Muy |

| PDY2 | Variation of friction Muy with load |

| PDY3 | Variation of friction Muy with squared camber |

| PEY1 | Lateral curvature Efy at Fznom |

| PEY2 | Variation of curvature Efy with load |

| PEY3 | Zero order camber dependency of curvature Efy |

| PEY4 | Variation of curvature Efy with camber |

| PEY5 | Variation of curvature Efy with camber squared |

| PKY1 | Maximum value of stiffness Kfy/Fznom |

| PKY2 | Load at which Kfy reaches maximum value |

| PKY3 | Variation of Kfy/Fznom with camber |

| PKY4 | Curvature of stiffness Kfy |

| PKY5 | Peak stiffness variation with camber squared |

| PKY6 | Fy camber stiffness factor |

| PKY7 | Vertical load dependency of camber stiffness factor |

| PHY1 | Horizontal shift Shy at Fznom |

| PHY2 | Variation of shift Shy with load |

| PVY1 | Vertical shift in Svy/Fz at Fznom |

| PVY2 | Variation of shift Svy/Fz with load |

| PVY3 | Variation of shift Svy/Fz with camber |

| PVY4 | Variation of shift Svy/Fz with camber and load |

| RBY1 | Slope factor for combined Fy reduction |

| RBY2 | Variation of slope Fy reduction with alpha |

| RBY3 | Shift term for alpha in slope Fy reduction |

| RBY4 | Influence of camber on stiffness of Fy combined |

| RCY1 | Shape factor for combined Fy reduction |

| REY1 | Curvature factor of combined Fy |

| REY2 | Curvature factor of combined Fy with load |

| RHY1 | Shift factor for combined Fy reduction |

| RHY2 | Shift factor for combined Fy reduction with load |

| RVY1 | Kappa induced side force Svyk/Muy*Fz at Fznom |

| RVY2 | Variation of Svyk/Muy*Fz with load |

| RVY3 | Variation of Svyk/Muy*Fz with camber |

| RVY4 | Variation of Svyk/Muy*Fz with alpha |

| RVY5 | Variation of Svyk/Muy*Fz with kappa |

| RVY6 | Variation of Svyk/Muy*Fz with atan(kappa) |

| PPY1 | Influence of inflation pressure on cornering stiffness |

| PPY2 | Influence of inflation pressure on dependency of nominal tire load on cornering stiffness |

| PPY3 | linear influence of inflation pressure on lateral peak friction |

| PPY4 | Quadratic influence of inflation pressure on lateral peak friction |

| PPY5 | Influence of inflation pressure on camber stiffness |

Rolling Coefficients

| QSY1 | Rolling resistance torque coefficient |

| QSY2 | Rolling resistance torque depending on Fx |

| QSY3 | Rolling resistance torque depending on speed |

| QSY4 | Rolling resistance torque depending on speed^4 |

| QSY5 | Rolling resistance torque depending on camber squared |

| QSY6 | Rolling resistance torque depending on load and camber squared |

| QSY7 | Rolling resistance torque coefficient load dependency |

| QSY8 | Rolling resistance torque coefficient pressure dependency |

Aligning Coefficients

| QBZ1 | Trail slope factor for trail Bpt at Fznom |

| QBZ2 | Variation of slope Bpt with load |

| QBZ3 | Variation of slope Bpt with load squared |

| QBZ4 | Variation of slope Bpt with camber |

| QBZ5 | Variation of slope Bpt with absolute camber |

| QBZ9 | Factor for scaling factors of slope factor Br of Mzr |

| QBZ10 | Factor for dimensionless cornering stiffness of Br of Mzr |

| QCZ1 | Shape factor Cpt for pneumatic trail |

| QDZ1 | Peak trail Dpt = Dpt*(Fz/Fznom*R0) |

| QDZ2 | Variation of peak Dpt with load |

| QDZ3 | Variation of peak Dpt with camber |

| QDZ4 | Variation of peak Dpt with camber squared |

| QDZ6 | Peak residual torque Dmr = Dmr/(Fz*R0) |

| QDZ7 | Variation of peak factor Dmr with load |

| QDZ8 | Variation of peak factor Dmr with camber |

| QDZ9 | Variation of peak factor Dmr with camber and load |

| QDZ10 | Variation of peak factor Dmr with camber squared |

| QDZ11 | Variation of Dmr with camber squared and load |

| QEZ1 | Trail curvature Ept at Fznom |

| QEZ2 | Variation of curvature Ept with load |

| QEZ3 | Variation of curvature Ept with load squared |

| QEZ4 | Variation of curvature Ept with sign of Alpha-t |

| QEZ5 | Variation of Ept with camber and sign Alpha-t |

| QHZ1 | Trail horizontal shift Sht at Fznom |

| QHZ2 | Variation of shift Sht with load |

| QHZ3 | Variation of shift Sht with camber |

| QHZ4 | Variation of shift Sht with camber and load |

| SSZ1 | Nominal value of s/R0: effect of Fx on Mz |

| SSZ2 | Variation of distance s/R0 with Fy /Fznom |

| SSZ3 | Variation of distance s/R0 with camber |

| SSZ4 | Variation of distance s/R0 with load and camber |

| PPZ1 | Effect of inflation pressure on length of pneumatic trail |

| PPZ2 | Influence of inflation pressure on residual aligning torque |

If you specify Slip Mode as Combined +

Turn, the turn slip coefficients are required.

Turn Slip Coefficients

| PDXP1 | Peak Fx reduction due to spin parameter |

| PDXP2 | Peak Fx reduction due to spin with varying load parameter |

| PDXP3 | Peak Fx reduction due to spin with kappa parameter |

| PKYP1 | Cornering stiffness reduction due to spin |

| PDYP1 | Peak Fy reduction due to spin parameter |

| PDYP2 | Peak Fy reduction due to spin with varying load parameter |

| PDYP3 | Peak Fy reduction due to spin with alpha parameter |

| PDYP4 | Peak Fy reduction due to square root of spin parameter |

| PHYP1 | Fy-alpha curve lateral shift limitation |

| PHYP2 | Fy-alpha curve maximum lateral shift parameter |

| PHYP3 | Fy-alpha curve maximum lateral shift varying with load parameter |

| PHYP4 | Fy-alpha curve maximum lateral shift parameter |

| PECP1 | Camber with respect to spin reduction factor parameter in camber stiffness |

| PECP2 | Camber with respect to spin reduction factor varying with load parameter in camber stiffness |

| QDTP1 | Pneumatic trail reduction factor due to turn slip parameter |

| QCRP1 | Turning moment at constant turning and zero forward speed parameter |

| QCRP2 | Turn slip moment (at alpha=90deg) parameter for increase with spin |

| QBRP1 | Residual (spin) torque reduction factor parameter due to side slip |

| QDRP1 | Turn slip moment peak magnitude parameter |

References

[1] Pacejka, Hans B., and Igo Besselink. Tire and Vehicle Dynamics. 3rd. Engineering Automotive Engineering. Amsterdam: Elsevier/Butterworth-Heinemann, 2012.

[2] Besselink, I. J.M., A. J.C. Schmeitz, and H. B. Pacejka. “An Improved Magic Formula/Swift Tyre Model That Can Handle Inflation Pressure Changes.” Vehicle System Dynamics 48, no. sup1 (December 2010): 337–52. https://doi.org/10.1080/00423111003748088.

[3] van der Hofstad, R. H. M. T. “Study on improving the MF-Swift tyre model.” (2010).

Version History

Introduced in R2021bUse the closest point or the weighted penetration method to compute the location and orientation of the contact frame between the tire and the contact surface.

Use the rho port to output the radial deflection. The radial deflection is the difference between the tire free radius and the loaded radius.

Use the Grid Surface block to represent the contact surface.

MATLAB Command

You clicked a link that corresponds to this MATLAB command:

Run the command by entering it in the MATLAB Command Window. Web browsers do not support MATLAB commands.

Select a Web Site

Choose a web site to get translated content where available and see local events and offers. Based on your location, we recommend that you select: .

You can also select a web site from the following list

How to Get Best Site Performance

Select the China site (in Chinese or English) for best site performance. Other MathWorks country sites are not optimized for visits from your location.

Americas

- América Latina (Español)

- Canada (English)

- United States (English)

Europe

- Belgium (English)

- Denmark (English)

- Deutschland (Deutsch)

- España (Español)

- Finland (English)

- France (Français)

- Ireland (English)

- Italia (Italiano)

- Luxembourg (English)

- Netherlands (English)

- Norway (English)

- Österreich (Deutsch)

- Portugal (English)

- Sweden (English)

- Switzerland

- United Kingdom (English)