operspec

Operating point specifications

Description

Examples

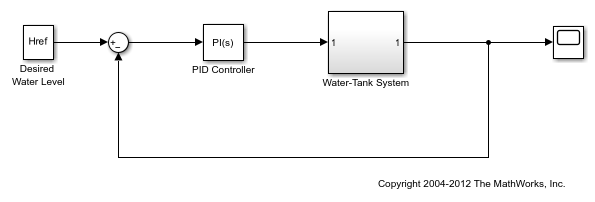

Open Simulink model.

sys = 'watertank';

open_system(sys)

Create the default operating point specification object for the model.

opspec = operspec(sys)

opspec =

Operating point specification for the Model watertank.

(Time-Varying Components Evaluated at time t=0)

States:

----------

x Known SteadyState Min Max dxMin dxMax

___________ ___________ ___________ ___________ ___________ ___________ ___________

(1.) watertank/PID Controller/Integrator/Continuous/Integrator

0 false true -Inf Inf -Inf Inf

(2.) watertank/Water-Tank System/H

1 false true 0 Inf -Inf Inf

Inputs: None

----------

Outputs: None

----------

opspec contains specifications for the two states in the model. Since the model has no root level inports or outports, opspec does not contain input or output specifications. To add output specifications, use addoutputspec.

Modify the operating point specifications for each state using dot notation. For example, configure the first state to:

Be at steady state.

Have a lower bound of

0.Have an initial value of

2for trimming.

opspec.States(1).SteadyState = 1; opspec.States(1).x = 2; opspec.States(1).Min = 0;

You can create new operspec variables in three ways:

Using the

operspeccommandUsing assignment with the equals (

=) operatorUsing the

copycommand

Using the = operator results in linked variables that both point to the same underlying data. Using the copy command results in an independent operspec object. In this example, create operspec objects both ways, and examine their behavior.

mdl = 'watertank';

open_system(mdl)

opspec1 = operspec(mdl)opspec1 =

Operating point specification for the Model watertank.

(Time-Varying Components Evaluated at time t=0)

States:

----------

x Known SteadyState Min Max dxMin dxMax

___________ ___________ ___________ ___________ ___________ ___________ ___________

(1.) watertank/PID Controller/Integrator/Continuous/Integrator

0 false true -Inf Inf -Inf Inf

(2.) watertank/Water-Tank System/H

1 false true 0 Inf -Inf Inf

Inputs: None

----------

Outputs: None

----------

Create a new operating point specification object using assignment with the = operator.

opspec2 = opspec1;

opspec2 is an operspec object that points to the same underlying data as opspec1. Because of this link, you cannot independently change properties of the two operspec objects. To see this, change a property of opspec2. For instance, change the initial value for the first state from 0 to 2. The change shows in the States section of the display.

opspec2.States(1).x = 2

opspec2 =

Operating point specification for the Model watertank.

(Time-Varying Components Evaluated at time t=0)

States:

----------

x Known SteadyState Min Max dxMin dxMax

___________ ___________ ___________ ___________ ___________ ___________ ___________

(1.) watertank/PID Controller/Integrator/Continuous/Integrator

2 false true -Inf Inf -Inf Inf

(2.) watertank/Water-Tank System/H

1 false true 0 Inf -Inf Inf

Inputs: None

----------

Outputs: None

----------

Examine the display of opspec1 to see that the corresponding property value of opspec1 also changes from 0 to 2.

opspec1

opspec1 =

Operating point specification for the Model watertank.

(Time-Varying Components Evaluated at time t=0)

States:

----------

x Known SteadyState Min Max dxMin dxMax

___________ ___________ ___________ ___________ ___________ ___________ ___________

(1.) watertank/PID Controller/Integrator/Continuous/Integrator

2 false true -Inf Inf -Inf Inf

(2.) watertank/Water-Tank System/H

1 false true 0 Inf -Inf Inf

Inputs: None

----------

Outputs: None

----------

To create an independent copy of an operating point specification, use the copy command.

opspec3 = copy(opspec1);

Now, when you change a property of opspec3, opspec1 does not change. For instance, change the initial value for the first state from 2 to 4.

opspec3.States(1).x = 4

opspec3 =

Operating point specification for the Model watertank.

(Time-Varying Components Evaluated at time t=0)

States:

----------

x Known SteadyState Min Max dxMin dxMax

___________ ___________ ___________ ___________ ___________ ___________ ___________

(1.) watertank/PID Controller/Integrator/Continuous/Integrator

4 false true -Inf Inf -Inf Inf

(2.) watertank/Water-Tank System/H

1 false true 0 Inf -Inf Inf

Inputs: None

----------

Outputs: None

----------

In opspec1, the corresponding value remains 2.

opspec1.States(1).x

ans = 2

This copy behavior occurs because operspec is a handle object. For more information about handle objects, see Handle Object Behavior.

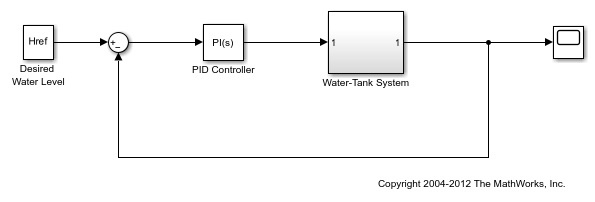

Open Simulink model.

sys = 'watertank';

open_system(sys)

Create a 2-by-3 array of operating point specification objects. You can batch trim model at multiple operating points using such arrays.

opspec = operspec(sys,[2,3]);

Each element of opspec contains a default operating point specification object for the model.

Modify the operating point specification objects using dot notation. For example, configure the second state of the specification object in row 1, column 3.

opspec(1,3).States(2).SteadyState = 1; opspec(1,3).States(1).x = 2;

You can also create multidimensional arrays of operating point specification objects. For example, create a 3-by-4-by-5 array.

opspec = operspec(sys,[3,4,5]);

Input Arguments

Simulink model name, specified as a character vector or string.

Array dimensions, specified as one of the following:

Integer — Create a column vector of

dimoperating point specification objects.Row vector of integers — Create an array of operating point specification objects with the dimensions specified by

dim.For example, to create a 4-by-5 array of operating point specification objects, use:

opspec = operspec(mdl,[4,5]);

To create a multidimensional array of operating point specification objects, specify additional dimensions. For example, to create a 2-by-3-by-4 array, use:

opspec = operspec(mdl,[2,3,4]);

Output Arguments

Operating point specifications, returned as an OperatingSpec object or an

array of such objects.

You can modify the operating point specifications using dot notation. For example, if

opspec is a single OperatingSpec

object, opspec.States(1).x accesses the state values of

the first model state. If opspec is an array of

OperatingSpec objects

opspec(2,3).Inputs(1).u accesses the input level of

the first inport block for the specification in row 2,

column 3.

Each OperatingSpec object has the following properties.

| Property | Description | ||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Model | Simulink model name, returned as a character vector. | ||||||||||||||||||||||||||||||

States | State operating point specifications, returned as a vector

of state specification objects. Each entry in For a

list of supported states for operating point objects, see Simulink Model States Included in Operating Point Object.

Edit the properties of this object using dot notation or the Note If the block has multiple named continuous states, Each state specification object has the following fields:

| ||||||||||||||||||||||||||||||

Inputs | Input level specifications at the operating point, returned

as a vector of input specification objects. Each entry in Each input specification object has the following fields:

| ||||||||||||||||||||||||||||||

Outputs | Output level specifications at the operating point, returned

as a vector of output specification objects. Each entry in You can specify

additional trim output constraints using Each output specification object has the following fields:

| ||||||||||||||||||||||||||||||

Time | Times at which the time-varying functions in the model are evaluated, returned as a vector. | ||||||||||||||||||||||||||||||

CustomObjFcn | Function providing an additional custom objective function for trimming, specified as a handle to the custom function, or a character vector or string that contains the function name. The custom function must be on the MATLAB® path or in the current working folder. You can specify a custom objective function as an algebraic combination of model states, inputs, and outputs. For more information, see Compute Operating Points Using Custom Constraints and Objective Functions. | ||||||||||||||||||||||||||||||

CustomConstrFcn | Function providing additional custom constraints for trimming, specified as a handle to the custom function, or a character vector or string that contains the function name. The custom function must be on the MATLAB path or in the current working folder. You can specify custom equality and inequality constraints as algebraic combinations of model states, inputs, and outputs. For more information, see Compute Operating Points Using Custom Constraints and Objective Functions. | ||||||||||||||||||||||||||||||

CustomMappingFcn | Function that maps model states, inputs, and outputs

to the vectors accepted by For complex models, you can pass subsets of the model inputs, outputs, and states to the custom constraint and objective functions using a custom mapping function. If you specify a custom mapping, you must use the mapping for both the custom constraint function and the custom objective function. For more information, see Compute Operating Points Using Custom Constraints and Objective Functions. |

Tips

To display the operating point specification object properties, use

get.You can create new

operspecvariables of in 3 ways:Construct a new object with the

operspeccommand.Create a new variable by assignment with the equals (=) operator.

Copy an

operspecobject using thecopycommand.

Using

operspecorcopycreates a new, independent object. When you use assignment, there is a link between the old and new variable. For an example, see Copy an Operating-Point Specification.

Version History

Introduced before R2006aThe input and output PortWidth properties of operating point

specifications will be removed in a future release. Use the new

Nu and Ny properties instead.

To update your code, change instances of PortWidth to either

Nu or Ny as shown in the following

table.

| Not Recommended | Recommended |

|---|---|

op = operspec('scdplane');

numOut = op.Outputs(1).PortWidth;

numIn = op.Inputs(1).PortWidth; |

op = operspec('scdplane');

numOut = op.Outputs(1).Ny;

numIn = op.Inputs(1).Nu; |

See Also

findop | addoutputspec | update | copy

MATLAB Command

You clicked a link that corresponds to this MATLAB command:

Run the command by entering it in the MATLAB Command Window. Web browsers do not support MATLAB commands.

Select a Web Site

Choose a web site to get translated content where available and see local events and offers. Based on your location, we recommend that you select: .

You can also select a web site from the following list

How to Get Best Site Performance

Select the China site (in Chinese or English) for best site performance. Other MathWorks country sites are not optimized for visits from your location.

Americas

- América Latina (Español)

- Canada (English)

- United States (English)

Europe

- Belgium (English)

- Denmark (English)

- Deutschland (Deutsch)

- España (Español)

- Finland (English)

- France (Français)

- Ireland (English)

- Italia (Italiano)

- Luxembourg (English)

- Netherlands (English)

- Norway (English)

- Österreich (Deutsch)

- Portugal (English)

- Sweden (English)

- Switzerland

- United Kingdom (English)