Metallurgists and process engineers use MATLAB and Simulink to optimize throughput, minimize downtime, and increase safety. They analyze real-time sensor data, model and simulate mining operations, implement control strategies, and leverage artificial intelligence systems.

MATLAB and Simulink help mining engineers:

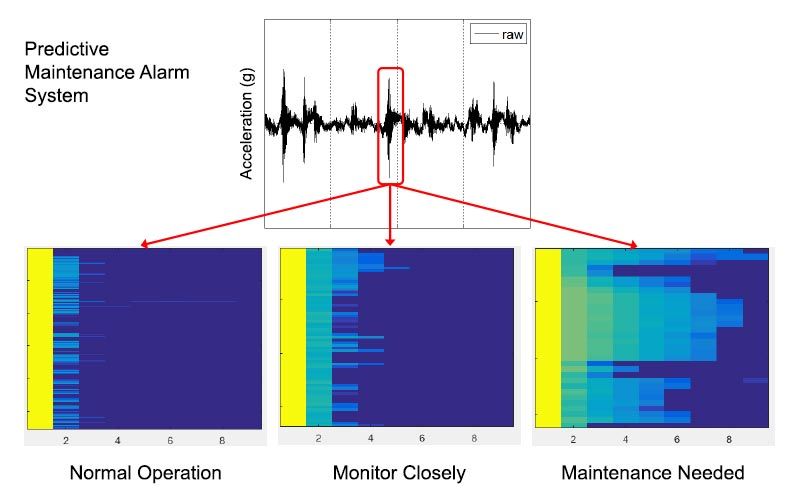

- Develop predictive maintenance systems by applying numerical techniques to high-speed sensor data

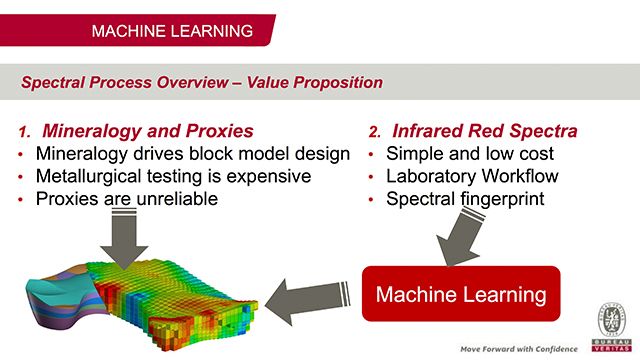

- Use machine learning with historical data to troubleshoot process problems

- Use plant and equipment modeling and simulation to improve process performance

- Co-operate with data scientists and IT personnel to adopt digitization

- Use a digital twin to continue plant operations when sensors are down

"MATLAB gave us the ability to convert previously unreadable data into a usable format; automate filtering, spectral analysis, and transform steps for multiple trucks and regions; and ultimately, apply machine learning techniques in real time to predict the ideal time to perform maintenance."

Gulshan Singh, Baker Hughes

Exploration

Extraction

Optimize Assets with Predictive Maintenance and Signal Processing

MATLAB can help you develop predictive maintenance algorithms customized to the specific operational and architectural profile of your equipment. Use Predictive Maintenance Toolbox to design condition indicators and estimate the remaining useful life of your rotary equipment.

You can use Signal Processing Toolbox to automate the monitoring of performance of your control loops, remotely determine the extent of corrosion or pitting in your pipelines, and detect the location and quantity of pipeline leaks.

Read how Baker Hughes used MATLAB to implement a predictive maintenance platform for gas and oil extraction equipment and reduced overall costs by 30-40%.

Processing

Machine Learning, Deep Learning, and Big Data

Interactive apps in Statistics and Machine Learning Toolbox let you apply machine learning techniques without having to be an expert in data science. MATLAB also provides a single, high-performance environment for working with big data and developing deep learning models. This enables you to perform fault detection and diagnosis faster and better monitor your processes.

Read how Ruukki engineers reduced their analysis times from several days to less than a minute by integrating various databases and using machine learning for process optimization.

Simulating Failure Data

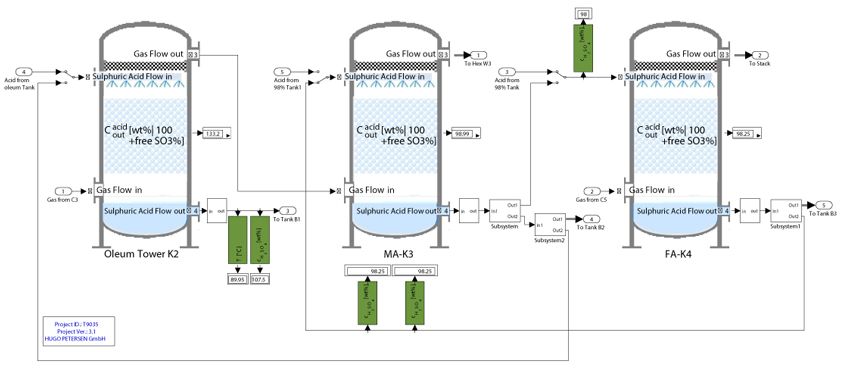

Traditionally, engineers optimize mining plants and processes based on data collected from sensors. However, sensor data is not always available for the multiple possible failure modes in a machine. Instead, you can use simulation data to represent failures by creating a model of your machine and simulating faulty operating conditions.

Simulink and Simscape enable you to build a model of your machine that can describe its behavior in terms of its physical components and dynamics. You can represent different failure modes of the machine by modifying parameter values, injecting faults, and changing model dynamics.

Process Improvement with Data Modeling

Use multivariate analysis tools in MATLAB to determine the independent driving variables affecting process performance. System Identification Toolbox lets you create and use models of dynamic systems that are not easily modeled from first principles or specifications. The toolbox also lets you interactively perform online parameter and state estimation.

Watch how Shell used MATLAB to develop models and perform real-time optimization on a batch process.

Develop and Deploy Process Control Algorithms with Virtual Commissioning

You can use MATLAB and Simulink products to design reliable algorithms and perform dynamic simulations to achieve desired results. MATLAB and Simulink let you validate your design with virtual commissioning by automatically generating algorithm code and testing it through software-in-the-loop, hardware-in-the-loop, and rapid prototyping approaches.

Learn more about how you can automatically generate code for production systems and connect directly with third-party platforms.

Watch (Part 1 and Part 2) how virtual commissioning helps reduce the risk of costly downtime while helping you save time and improve system performance.

Read how Tata Steel saved 40% energy on their industrial cooling towers by optimizing the control strategy through a digital twin.

Supply Chain Logistics and Production Forecasting

Simplify Planning and Scheduling Activities

Improve efficiencies in production and scheduling through discrete event simulation. With SimEvents, you can study the effects of task timing and resource usage in a batch production process. Using MATLAB and Simulink products, you can also conduct operational research for decisions related to forecasting, capacity planning, and supply-chain management.

Learn how GE Transportation developed a drive assistance system for locomotives using MATLAB.

Production Forecasting for Mining Operations with Simulation

Optimizing Scheduling and Blending Operations in the Process Industries (32:00)

Digital Transformation

Digitization

MathWorks can help you adopt and implement big data strategies specific to the needs of your organization. You can use prebuilt MATLAB toolboxes and reference architectures to simplify a wide range of applications: from integrating with enterprise IT systems, the cloud, and production data infrastructure to scaling your computation to clusters or deploying your models as applications to share with users outside of MATLAB. See how you can achieve this on the cloud.

Learn more about how you can also connect directly with AVEVA™ PI systems.

Watch how Shell embraced digitization using MATLAB Production Server. Shell engineers automated their processes for integrating data from different sources, building models, and deploying their analytics onto cloud and enterprise systems.

“MATLAB enabled us, as geologists, to use our expertise in predictive frameworks, analytics, and analog matching to implement algorithms that are unique in our industry. With the help of MathWorks consultants, we then deployed those algorithms as an easy-to-use application to our colleagues worldwide.”

Nick Howes, Shell

Let us know how we can help you.

Contact us for a custom evaluation, and get pricing based on your needs.