FEM-Parameterized Induction Machine (Wound Rotor)

Wound-rotor induction machine defined in terms of magnetic flux linkage

Since R2023b

Libraries:

Simscape /

Electrical /

Electromechanical /

Asynchronous

Description

The FEM-Parameterized Induction Machine (Wound Rotor) block models a wound-rotor induction machine using magnetic flux linkage tables.

You can generate the magnetic flux linkage tables with a finite element tool such as ANSYS Motor-CAD software.

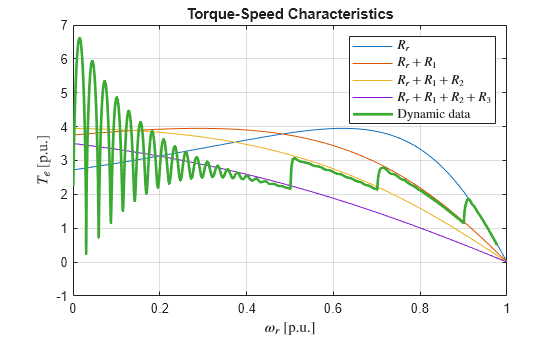

A wound-rotor asynchronous machine is a type of induction machine. You can access all the stator and rotor connections on the block. Therefore, you can model soft-start regimes using a switch between wye and delta configurations or by increasing rotor resistance. If you do not need access to the rotor windings, you can use the FEM-Parameterized Induction Machine (Squirrel Cage) block instead.

Connect port ~1 to a three-phase circuit. To connect the stator in delta configuration, connect a Phase Permute block between ports ~1 and ~2. To connect the stator in wye configuration, connect port ~2 to a Grounded Neutral (Three-Phase) or Floating Neutral (Three-Phase) block.

If you do not need to vary the rotor resistance, connect the rotor port ~1r' to a Floating Neutral (Three-Phase) block and rotor port ~2r' to a Grounded Neutral (Three-Phase) block.

The rotor circuit is referred to the stator. Therefore, when you use the block in a circuit, refer any additional circuit parameters to the stator.

Equations

A three-phase wound-rotor induction machine consists of an iron stator lamination with three copper windings and a rotor lamination with three copper windings.

When a three-phase AC supply feeds the stator, the current produces a rotating magnetic field. This rotating field induces currents in the rotor windings, which produce a magnetic field in the rotor. The interaction between these magnetic fields and the currents produces a torque in the rotor, which starts its motion.

The induction machine equations are expressed in a synchronous reference frame orientated with the rotor field (SRFORF). This frame is synchronous with the stator and rotor magnetic fields, and the D-axis is aligned with the rotor field D-axis. The rotor magnetic flux linkage vector only has a D-axis component in this frame. The Q-axis component is zero.

is the stator magnetic field vector.

is the rotor magnetic field vector.

is the stator current vector.

All of these vectors rotate at the synchronous speed ωe. The synchronous angle θe tracks the orientation of the stator current vector.

The rotor current vector rotates at a speed given by this equation:

where ωr is the rotor mechanical speed and Npp is the Number of pole pairs parameter.

To express the stator a-, b-, and c-phase voltages and currents in the SRFORF reference frame, you can use the Park transform:

where θe is the time integral of the synchronous speed:

You can then compute the D-axis and Q-axis components of stator voltages and currents using these equations.

The rotor a-, b-, and c-phase voltages and currents do not rotate at the synchronous speed due to slip. Rotor currents rotate at the slip speed ωslip.

To express rotor DQ currents in the stationary frame (a, b, and c phases) you can use the Park transform:

where θer is the rotor slip angle, equal to the time integral of the slip speed:

Then, you can compute the a, b, and c components of rotor voltages and currents using these equations.

In the SRFORF reference frame, the stator and rotor currents, voltages, and fluxes are related to these fundamental induction machine equations:

Stator voltage equations

Rotor voltage equations

Use the latter rotor voltage equation to compute the slip speed, which you can then use to compute the synchronous speed for the reference frame transformations.

Wound rotor equations

where Vrd and Vrq are the D-axis and Q-axis rotor voltages across ports ~1r' and ~2r', respectively.

Flux-current relationships

The magnetizing D-axis current is defined as

and the flux-current relationships are

where:

λds is the interpolated value of the Stator d-axis flux linkage table, λds(ids,iqs) parameter computed for the particular combination of id and iqs.

λqs is the interpolated value of the Stator q-axis flux linkage table, λqs(ids,iqs) parameter computed for the particular combination of id and iqs.

Lt is the interpolated value of the transient inductance computed from the magnetic flux linkage tables.

An alternative form of the rotor flux-current relationships uses the Lϕ inductance

where Lϕ is the interpolated value of the magnetizing inductance table computed from the flux linkage tables.

When you combine the latter equation for the Q-axis rotor flux with you obtain , which means that the referred rotor Q-axis current is equal and opposite to the stator Q-axis current:

Lϕ is defined by this equation.

where Lt is the transient inductance is defined as

In these equations Ls, Lm, and are the stator inductance, the magnetizing inductance, and the referred rotor inductance respectively. These equations relate these inductances:

where Lls and are the stator leakage inductance and the referred rotor leakage inductance, respectively.

Torque equation

Model Thermal Effects

You can expose thermal ports to simulate the effects of generated heat and motor temperature. To expose the thermal ports and enable the Temperature Dependence and Thermal Port parameters, set the Modeling option parameter to one of these options:

No thermal port— The block contains electrical conserving ports associated with the stator windings, but does not contain thermal ports.Show thermal port— The block contains expanded electrical conserving ports associated with the stator windings and thermal conserving ports for each of the windings and for the rotor.

For more information about using thermal ports in actuator blocks, see Simulating Thermal Effects in Rotational and Translational Actuators.

Variables

To set the priority and initial target values for the block variables before simulation, use the Initial Targets section in the block dialog box or Property Inspector. For more information, see Set Priority and Initial Target for Block Variables.

Nominal values provide a way to specify the expected magnitude of a variable in a model. Using system scaling based on nominal values increases the simulation robustness. You can specify nominal values using different sources, including the Nominal Values section in the block dialog box or Property Inspector. For more information, see System Scaling by Nominal Values.

Examples

Ports

Conserving

Parameters

References

[1] Carbonieri, Matteo, Nicola Bianchi, and Luigi Alberti. “Induction Motor Mapping Using Rotor Field-Oriented Analysis Technique.” In 2019 IEEE Energy Conversion Congress and Exposition (ECCE), 2321–28. Baltimore, MD, USA: IEEE, 2019. https://doi.org/10.1109/ECCE.2019.8912787.

[2] Carbonieri, Matteo, Lino Di Leonardo, Marco Tursini, Marco Villani, and Mircea Popescu. “Induction Motor Performance Prediction Using Static FEA: Method Description and Comparison With Time-Domain Approach.” In 2020 IEEE Energy Conversion Congress and Exposition (ECCE), 1351–56. Detroit, MI, USA: IEEE, 2020. https://doi.org/10.1109/ECCE44975.2020.9236246.

[3] Troncon, Diego, Matteo Carbonieri, Luigi Alberti, and Nicola Bianchi. “Measures and Simulations of Induction Machines Flux Linkage Characteristics Based on Rotor Field Orientation.” IEEE Transactions on Industry Applications 57, no. 5 (September 2021): 4686–93. https://doi.org/10.1109/TIA.2021.3089662.

Extended Capabilities

Version History

Introduced in R2023b