Calibrate Mapped CI Engine Using Data

If you have Model-Based Calibration Toolbox™, the Virtual Vehicle Composer can use a data set to calibrate a mapped compression-ignition (CI) engine in the vehicle.

Use this Virtual Vehicle Composer app-based workflow to evaluate system-level performance, economy, and emissions. To develop plant controls for engines and motors, consider using the dynamometer reference applications. For more information, see Calibrate and Resize Engines and Electric Motors.

Open the Virtual Vehicle Composer app.

On the Setup tab:

Specify your virtual vehicle options, including Vehicle class, Model template, and Vehicle dynamics.

Set Powertrain architecture to a configuration that uses a CI engine, for example,

Conventional Vehicle.Click Configure.

On the Data and Calibration tab, select Powertrain > Engine.

In the Engine list, select

CI Mapped Engine.Select the Calibrate from Data tab.

Use the Firing Data and Nonfiring Data boxes to provide data files. By default, the app uses the file

CiEngineData.xlsx, which contains required and optional data. The tables summarize the data file requirements for generating calibrated tables that are functions of either injected fuel mass or engine torque and engine speed.Firing data contains data collected at different engine torques and speeds.

Firing Data Description Data Requirements for Generating Mapped Engine Tables Function of Fuel Mass and Engine Speed Function of Torque and Engine Speed FuelMassCmd Injected fuel mass, in mg per injection

Required

Not used

Torque Engine torque command, in N·m

Required Required EngSpd Engine speed, in rpm

Required Required AirMassFlwRate Air mass flow, in kg/s

Optional

Optional

FuelMassFlwRate Fuel mass flow, in kg/s

Optional

Optional

ExhTemp Exhaust temperature, in K

Optional

Optional

BSFC Engine brake-specific fuel consumption (BSFC), in g/kWh

Optional

Optional

HCMassFlwRate Hydrocarbon emission mass flow, in kg/s

Optional

Optional

COMassFlwRate Carbon monoxide emission mass flow, in kg/s

Optional

Optional

NOxMassFlwRate Nitric oxide and nitrogen dioxide emissions mass flow, in kg/s

Optional

Optional

CO2MassFlwRate Carbon dioxide emission mass flow, in kg/s

Optional

Optional

PMMassFlwRate Particulate matter emission mass flow, in kg/s

Optional

Optional

Nonfiring data contains data collected at different engine speeds without fuel consumption.

Nonfiring Data Description Data Requirements for Generating Mapped Engine Tables Function of Fuel Mass and Engine Speed Function of Torque and Engine Speed FuelMassCmd Injected fuel mass, in mg per injection

Not used

Not used

Torque Engine torque command, in N·m

Required

Required

EngSpd Engine speed, in rpm

Required

Required

AirMassFlwRate Air mass flow, in kg/s

Optional

Optional

Click Calibrate to generate response surface models in the Model-Based Calibration Toolbox and calibration in CAGE (CAlibration GEneration). To calibrate the data, Model-Based Calibration Toolbox uses templates.

If prompted, select the firing or non-firing data sheets. Click OK.

When the process completes, the app updates the powertrain subsystem Mapped CI Engine block parameters with the calibrated data.

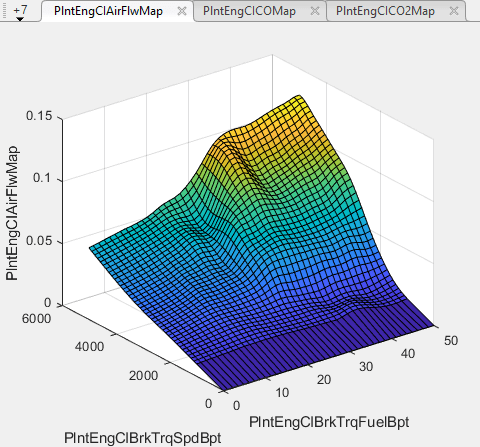

Review the engine characteristics response surface models, for example, air mass flow.

Optionally, to use additional calibration options, click Open Calibration Tool. The Model-Based Calibration Toolbox opens.

The Model Browser provides the response model fits for the data contained in the data file.

The CAGE Browser provides the calibrated data.

For information, see Model-Based Calibration Toolbox.

See Also

Topics

- What Is CAGE? (Model-Based Calibration Toolbox)

- Mapped CI Lookup Tables as Functions of Fuel Mass and Engine Speed (Model-Based Calibration Toolbox)

- Mapped CI Lookup Tables as Functions of Engine Torque and Speed (Model-Based Calibration Toolbox)

- Generate Mapped CI Engine from Spreadsheet

- Model Assessment (Model-Based Calibration Toolbox)

- Using Data (Model-Based Calibration Toolbox)