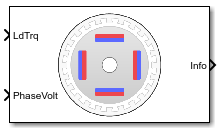

Interior PMSM

Three-phase interior permanent magnet synchronous motor with sinusoidal back electromotive force

Libraries:

Powertrain Blockset /

Propulsion /

Electric Motors and Inverters

Motor Control Blockset /

Electrical Systems /

Motors

Description

The Interior PMSM block implements a three-phase interior permanent magnet synchronous motor (PMSM) with sinusoidal back electromotive force. The block uses the three-phase input voltages to regulate the individual phase currents, allowing control of the motor torque or speed.

By default, the block sets the Simulation

type parameter to Continuous to use a

continuous sample time during simulation. If you want to generate code for fixed-step

double- and single-precision targets, considering setting the parameter to

Discrete. Then specify a Sample Time,

Ts parameter.

On the Parameters tab, if you

select Back-emf constant (Ke), the block implements this

equation to calculate the permanent flux linkage constant.

Motor Construction

This figure shows the motor construction with a single pole pair on the rotor.

The motor magnetic field due to the permanent magnets creates a sinusoidal rate of change of flux with motor angle.

For the axes convention, the a-phase and permanent magnet fluxes are aligned when motor angle θr is zero.

Three-Phase Sinusoidal Model Electrical System

The block implements these equations, expressed in the motor flux reference frame (dq frame). All quantities in the motor reference frame are referred to the stator.

The Lq and Ld inductances represent the relation between the phase inductance and the motor position due to the saliency of the motor.

The equations use these variables.

Lq, Ld | q- and d-axis inductances (H) |

R | Resistance of the stator windings (ohm) |

iq, id | q- and d-axis currents (A) |

vq, vd | q- and d-axis voltages (V) |

ωm | Angular mechanical velocity of the motor (rad/s) |

ωe | Angular electrical velocity of the motor (rad/s) |

λpm | Permanent flux linkage constant (Wb) |

Ke | Back electromotive force (EMF) (Vpk_LL/krpm, where Vpk_LL is the peak voltage line-to-line measurement) |

P | Number of pole pairs |

Te | Electromagnetic torque (Nm) |

Θe | Electrical angle (rad) |

Mechanical System

The motor angular velocity is given by:

The equations use these variables.

J | Combined inertia of motor and load (kgm^2) |

F | Combined viscous friction of motor and load (N·m/(rad/s)) |

θm | Motor mechanical angular position (rad) |

Tm | Motor shaft torque (Nm) |

Te | Electromagnetic torque (Nm) |

Tf | Motor shaft static friction torque (Nm) |

ωm | Angular mechanical velocity of the motor (rad/s) |

Power Accounting

For the power accounting, the block implements these equations.

| Bus Signal | Description | Variable | Equations | ||

|---|---|---|---|---|---|

|

|

| Mechanical power | Pmot | |

PwrBus | Electrical power | Pbus | |||

|

| PwrElecLoss | Resistive power loss | Pelec | ||

PwrMechLoss | Mechanical power loss | Pmech | When Mechanical input

configuration is set to

When Mechanical

input configuration is set to

| ||

|

| PwrMtrStored | Stored motor power | Pstr | ||

The equations use these variables.

Rs | Stator resistance (ohm) |

ia, ib, ic | Stator phase a, b, and c current (A) |

isq, isd | Stator q- and d-axis currents (A) |

van, vbn, vcn | Stator phase a, b, and c voltage (V) |

ωm | Angular mechanical velocity of the rotor (rad/s) |

F | Combined motor and load viscous damping (N·m/(rad/s)) |

Te | Electromagnetic torque (Nm) |

Tf | Combined motor and load friction torque (Nm) |

Amplitude Invariant dq Transformation

The block uses these equations to implement the amplitude invariant dq transformation to ensure that the dq and three phase amplitudes are equal.

The equations use these variables.

Θda | dq stator electrical angle with respect to the rotor a-axis (rad) |

vsq, vsd | Stator q- and d-axis voltages (V) |

isq, isd | Stator q- and d-axis currents (A) |

| va, vb, vc | Stator voltage phases a, b, c (V) |

| ia, ib, ic | Stator currents phases a, b, c (A) |

Ports

Input

Output

Parameters

References

[1] Kundur, P. Power System Stability and Control. New York, NY: McGraw Hill, 1993.

[2] Anderson, P. M. Analysis of Faulted Power Systems. Hoboken, NJ: Wiley-IEEE Press, 1995.

Extended Capabilities

Version History

Introduced in R2017a

See Also

Interior PM Controller | Flux-Based PMSM | Induction Motor | Mapped Motor | Surface Mount PMSM

Topics

- Estimate Motor Parameters Using Motor Control Blockset Parameter Estimation Tool (Motor Control Blockset)